Procurement is one of the corporate functions which has evolved dramatically over the years. The strategic nature of procurement has changed radically and is now recognized as a key contributor to a company’s success. LCC sourcing has led many companies to invest in manufacturing facilities in emerging countries. These units are established to promote exports to high-cost countries. They have also helped create a foundation so companies can sell their products and services in the local low-cost countries as well.

Although cost reduction has been the strongest motivation for Asia procurement, capacity management and alternate sources of supply for business continuity have also emerged as important motivators. However, organizations have realized that significant challenges remain to be tackled especially with distant supplier markets. Rising concerns about the best means to deal with them have led many companies to choose to work with a procurement service provider.

What to Move – Functions or Factories

When companies set up assembly plants or manufacturing units in LCCs, they need to ensure that they source most of the components locally as well. If they do not rely on product localization, the finished product – assembled based on imported components from high-cost countries -might end up far more expensive than their local competitors. They should try to find qualified suppliers locally so they do not have to rely on those located in high-cost countries such as the US, EU, and Japan.

With the number of western countries rushing to LCCs to strengthen links across supply chains, procurement’s role has become increasingly important. When conducted with rigorous processes, China product localization can be the answer for optimal management of supply chains. However, if not carefully analyzed and planned it could be a source of woe for your organization. Procurement service providers will work hand in hand with their local buying team to identify, develop, and qualify local suppliers. It also helps companies manage the temporary surge in procurement capacity that is needed to obtain the desired results.

Low-Cost Country Sourcing – The Buzzword

Although companies around the world are adopting LCC strategies, many are still unaware of risks related to quality, logistics, social responsibility, and intellectual property. For guaranteed success, it is important to establish strong relationships on the supplier side while maintaining competitive pressure. Strategic thinking is essential in terms of what, where, and how to conduct your product localization programme.

While some companies are viewing it as “critical” for their cost strategy, others are not too sure which costs to delocalise or how they need to go about the organizational changes that product localization in LCCs requires. Many others miss these opportunities because they are worried about the risks beyond their control in these countries.

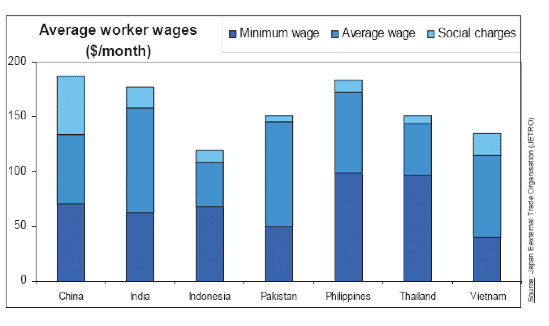

Procurement companies can provide you with the requisite market data and information to help you make informed decisions. For instance, you can refer to the image below for the Relative Labor Cost Position in LCCs.

Migrate Manufacturing Costs

Global sourcing has emerged as a fundamental strategic objective for most western companies. They are beginning to rely on improved capabilities and the labor available in these countries to target complex activities such as high-value-added manufacturing, engineering, and R&D as well. China is a fundamental part of most organization’s low-cost sourcing strategy. They consider establishing a physical presence in China as critical for LCC success. As part of this strategy, retaining experienced procurement service providers able to design and execute well-architected strategies and support your product localization initiative is a strategy adopted by many companies looking to accelerate their time-to-benefit realisation.